The Dummies Guide to Repairing Concrete

Concrete is a cornerstone of modern construction, prized for its durability, strength, and versatility. However, even the most robust concrete structures are not immune to damage. Environmental factors, wear and tear, and poor installation can all lead to deterioration over time. When damage occurs, timely and effective repair becomes critical to prolong the lifespan of the structure and ensure safety.

Common Causes of Concrete Damage

Before diving into the repair process, it’s essential to understand what causes concrete to deteriorate. Common factors include:

- Weathering and Environmental Conditions: Freeze-thaw cycles, exposure to water, and fluctuating temperatures can cause cracking and spalling.

- Chemical Attack: Sulphates, chlorides, and acids in the environment or within de-icing salts can corrode reinforcement and weaken the concrete matrix.

- Mechanical Damage: Heavy loads, impact, and abrasion can wear down concrete surfaces.

- Poor Construction Practices: Insufficient curing, inadequate mix design, or improper compaction can lead to weak, porous concrete.

- Ageing and Fatigue: Over time, even the best concrete structures succumb to cumulative stress and degradation.

Assessing the Damage

Accurate assessment is the first step in any concrete repair process. A professional inspection can determine the extent and cause of the damage. Methods used to assess concrete include:

- Visual Inspection: Identifying cracks, spalling, or discoloration.

- Non-Destructive Testing (NDT): Techniques like ground-penetrating radar (GPR) and ultrasonic pulse velocity (UPV) to detect internal flaws.

- Core Sampling: Extracting concrete samples to test compressive strength and other properties.

Understanding the type and severity of the damage helps inform the choice of repair method.

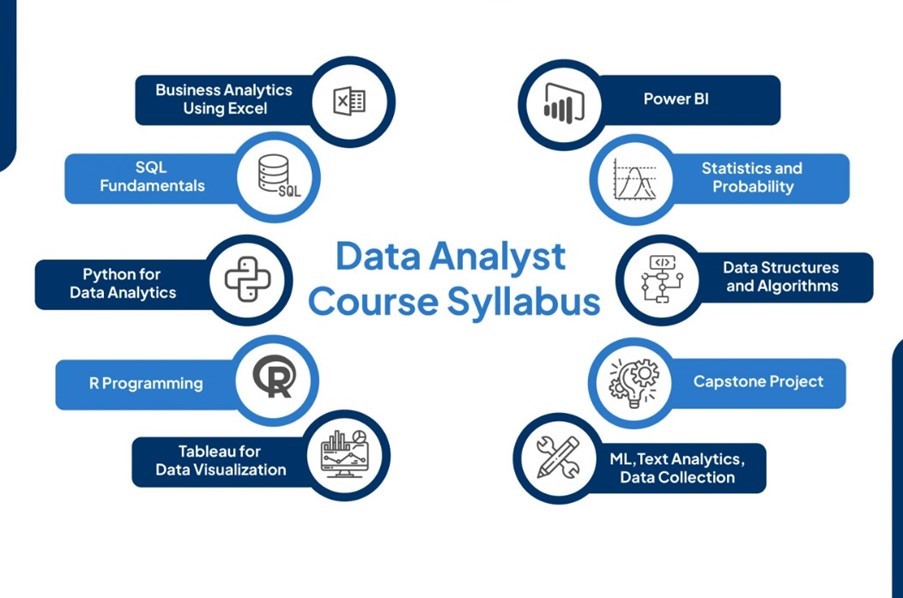

Methods for Repairing Concrete

How To Repair Concrete | Pro Tips For Repairing Concrete

There are several methods available for repairing damaged concrete, each suited to specific types of issues. These include:

- Crack Injection

Crack injection is a common method for repairing structural cracks. It involves injecting a specialised resin, such as epoxy or polyurethane, into the crack to seal it and restore the structural integrity.

- Epoxy Injection: Ideal for structural repairs where the crack width is narrow.

- Polyurethane Injection: Suited for sealing active or water-leaking cracks due to its flexibility.

- Surface Patching

Surface patching is used for repairing superficial damage such as spalling or scaling. The process involves:

- Cleaning the damaged area.

- Applying a bonding agent to ensure adhesion.

- Filling the area with a repair mortar or concrete mix.

- Finishing and curing the patched surface.

- Concrete Resurfacing

For widespread surface damage, resurfacing can rejuvenate the concrete. A polymer-modified overlay is applied over the existing surface to restore appearance and functionality.

- Reinforcement Repair

When reinforcement steel within the concrete corrodes, it expands and causes cracking. Repair involves:

- Removing damaged concrete around the reinforcement.

- Cleaning or replacing corroded steel.

- Applying a corrosion-inhibiting coating.

- Recasting with high-strength repair mortar.

- Shotcrete or Gunite Application

Shotcrete involves spraying a high-strength concrete or mortar mix onto a prepared surface. It is particularly effective for large vertical or overhead repairs, such as tunnel linings and retaining walls.

- Cathodic Protection

For structures exposed to corrosive environments, cathodic protection prevents further corrosion of reinforcement steel. This involves installing sacrificial anodes or impressed current systems to counteract corrosive forces.

Best Practices in Concrete Repair

Regardless of the method chosen, adhering to best practices ensures long-lasting repairs:

- Proper Surface Preparation: The substrate must be clean, sound, and free of contaminants.

- Selecting the Right Materials: Use repair materials compatible with the existing concrete in terms of strength, thermal expansion, and durability.

- Curing: Proper curing is essential to achieve maximum strength and durability.

- Adhering to Standards: Follow industry standards like BS EN 1504 (European standard for concrete repair) to ensure quality and safety.

Concrete Remediation: A Comprehensive Approach

Concrete remediation goes beyond simple repairs. It involves a holistic approach to restoring and protecting concrete structures, addressing underlying issues to prevent future damage. Key aspects of concrete remediation include:

- Diagnosis and Prevention

Understanding the root cause of deterioration allows engineers to implement preventative measures. For example, sealing concrete to prevent water ingress or applying protective coatings can mitigate future damage.

- Structural Strengthening

In some cases, additional reinforcement is necessary to meet updated load requirements or compensate for lost capacity. Techniques include:

- Carbon fiber-reinforced polymer (CFRP) wrapping.

- External post-tensioning.

- Section enlargement using additional concrete.

- Durability Enhancement

Improving the durability of the repaired structure is critical. Measures such as using corrosion inhibitors, water repellents, or advanced sealants can extend the life of the structure.

- Monitoring and Maintenance

Regular inspection and maintenance help detect issues early, ensuring the longevity of repairs. Embedded sensors or IoT-based systems can monitor structural health in real-time.

Case Study: Concrete Remediation in Practice

A notable example of concrete remediation is the repair of ageing bridges in urban areas. In one project, engineers faced significant challenges with a heavily corroded bridge deck that was crucial for traffic flow. To address the damage, a comprehensive remediation strategy was employed:

- Hydrodemolition: High-pressure water jets were used to remove deteriorated concrete without causing further harm to the embedded reinforcement. This method ensured precision and preserved the structural integrity of the remaining concrete.

- Reinforcement Cleaning and Replacement: The exposed reinforcement steel was thoroughly cleaned to remove corrosion. Severely damaged sections were replaced to restore strength.

- Cathodic Protection: To prevent future corrosion, an impressed current cathodic protection system was installed. This involved embedding anodes into the concrete and connecting them to a power source to counteract corrosion-inducing electrochemical reactions.

- Polymer Overlays: A durable polymer-modified overlay was applied to the bridge deck surface. This not only enhanced wear resistance but also provided a protective barrier against water and de-icing salts.

- Traffic Load Management: During the repair process, a phased construction approach was adopted to maintain partial traffic flow and minimise disruption. This required careful planning and coordination.

Post-remediation monitoring systems were installed to track the health of the bridge over time. Sensors embedded within the structure now provide real-time data on factors such as strain, temperature, and moisture levels, enabling proactive maintenance.

The project was completed within the allocated timeline and budget, restoring the bridge to full operational capacity while significantly extending its lifespan. This case study demonstrates the effectiveness of integrating advanced techniques and technologies in concrete remediation to achieve durable, long-term results.

Conclusion

Concrete repair is vital for maintaining the integrity and safety of structures. From addressing superficial cracks to undertaking large-scale remediation projects, the techniques and materials available today make it possible to extend the life of concrete structures significantly. By combining repair methods with preventative measures, professionals can ensure that concrete continues to stand the test of time. Whether you’re dealing with a cracked driveway or a corroded bridge, understanding the principles of concrete repair and remediation is the key to success.